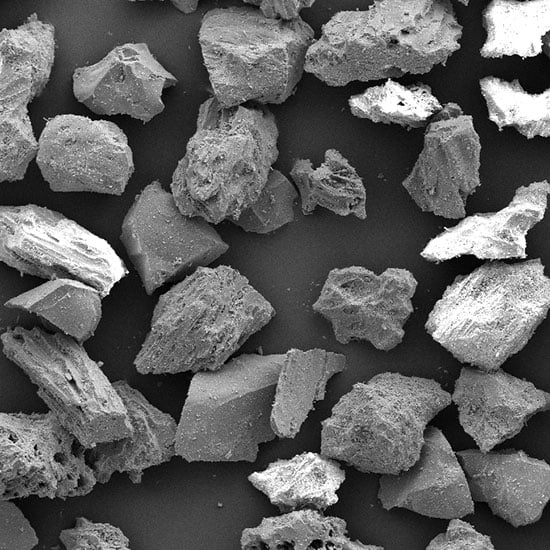

BORN OF EARTH AND FIRE, pumice is formed during volcanic pyroclasic events, typically spewed as ash that falls and drifts into deposits or as part of a massive pyroclastic flow. Many factors affect the useful quality, color, and purity of a pumice deposit, but on a chemical analysis level, pumice is basically an aluminum silicate. With no crystalline structure, pumice is a naturally calcined amorphous glass made up of a maze of air-filled vesicles.

The word pumice is derived from the Latin word pumex, meaning foam. Deep underground, molten rock incorporates water and other gases, and when the magma erupts from a volcanic vent, the gases flash off, leaving behind a frothy, vesicle-riven structure that quickly cools, solidifying the foamy structure.

Pumice enjoys a well-deserved green cred, as it is an abundant and sustainable resource, easily mined from surface deposits, and, having been naturally calcined (super-heated) in the fiery heat of a volcano, the only refining needed is to crush and screen it to grade.

Uses for Pumice

PUMICE PROVED ITS HISTORICAL VALUE to industry when Roman engineers combined pumice aggregate and fine-grained pumice (a pozzolan) with their hydrated lime cement to make a lightweight, enduring concrete. Many of their mighty concrete works still stand some two millennia later. Today, pumice is still being used as a superior pozzolan to super-charge concrete, but is also used widely in a variety of industrial process and product applications.

Pumice is amazingly versatile—used as a gentle polishing and cleansing abrasive, as lightweight aggregate and/or ultra-refined pozzolan in concrete, as a non-crystalline silica filler for paints, plastics and rubber compounds, as a soil conditioner, as a filtration media, and more.

That kind of versatility comes from a number of nature-blessed characteristics that combine to make it a valuable and widely applicable across a variety of industrial processes and products.

Pumice is amorphous and generally inert, has a neutral pH, yet is hard enough to be used as an abrasive. Yet, because of its porous nature, pumice is amazingly lightweight.

The friable nature of pumice is one of its most significant characteristics—meaning pumice is easily crushed and refined without loosing its utility: at any grade—from half-inch aggregate to microfine powder—pumice remains abrasive, absorbent, non-compacting, lightweight.

Sustainable and abundant, pumice is indispensable.

Grouped by attribute, the following is a breakdown of where and how pumice is used.

INDUSTRIAL ABRASIVE: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

PRODUCT ABRASIVE: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

MANUFACTURING AND FINISHING PROCESSES: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

FILTRATION: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

ABSORBENT, SPILL CONTAINMENT: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

HORTICULTURE, SOIL AMENDMENT: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

FILLERS AND EXTENDERS: There are several key consideration criteria for selecting an exfoliant or scrub grit. One of the first is a track record: pumice has proven highly effective for use in exfoliating products.

CONCRETE AND CEMENTITIOUS GROUTS: Pumice got its historical start as a useful agent when the Romans used it (known as pozzolan) to densify and strengthen their concrete—building enduring structures that still stand some two millenia later. Today, adding pumice pozzolan to concrete mix designs results in concrete that is highly resistant to ASR, sulfate attack, and chloride ingress, exhibits reduced thermal cracking, cures to form a nearly impermeable, highly-durable barrier that resists staining, cleans easily, and performs predictably, and continues to strengthen for years due to its pozzolanic charge.

Pumice concrete is composed of Portland Cement, pumice aggregate, pumice sand, pumice pozzolan, and water. Compared to regular concrete, pumice concrete offers roughly a one-third reduction in weight. Proportioning, mixing and placing are done in a similar manner to that of conventional concrete, as is the finishing. The applications for pumice concrete are also the same as those of standard sand-and-gravel concrete, but is particularly useful where lightweight concrete is desirable.

» Use the PUMICE STORE APPLICATIONS DIRECTORY to further explore the many uses for pumice and purchase the typical grades used for those applications.

» There are several MADE-LIKE-PUMICE PRODUCTS in the marketplace. Learn how pumice compares to each of these heat-expanded products in form-factor and use/application by downloading the whitepape: Pumice vs. X. Or visit the Pumice vs. X website.

» Learn more about HESS PUMICE PRODUCTS, the company that mines and refines the purest deposit of white pumice on the planet.

Technical Data

DESCRIPTION:

Amorphous (non-crystalline) in structure and composed primarily of aluminum silicate, pumice is a naturally calcined volcanic glass foam consisting of highly vesicular strands permeated with tiny air bubbles. It is these frothy, friable glass vesicles that, when carefully refined to various grades, give pumice its unique and infinitely useful qualities.

PHYSICAL PROPERTIES OF PUMICE:

Description: Non-crystalline (amorphous) foamed glass stone of volcanic origin. Grey-white (stone grades) to white (powder grades) in appearance.

Brightness: (GE) 84

Hardness: (MOHS) 6

Reactivity: Inert (except in the presence of calcium hydroxide or hydrofluoric acid)

pH: 7.2 (neutral)

Loose Bulk Density: Varies with grade (Download Technical Data Sheet of specific product below)

Specific Gravity: 2.35

Softening Point: 900 Degrees C

Water Soluble Substances: 0.15%

Radioactivity: None

CHEMICAL OF PROPERTIES OF PUMICE:

Chemical Name: Amorphous Aluminum Silicate

Composition: Primarily made up of Silicon Dioxide and Aluminum Oxide with traces of other oxides.

Silicon Dioxide: 76.2%

Aluminum Oxide: 13.5%

Ferric Oxide: 1.1%

Ferrous Oxide: 0.1%

Sodium Oxide: 1.6%

Potassium Oxide: 1.8%

Calcium Oxide: 0.8%

Titanium Oxide: 0.2%

Magnesium Oxide: 0.05%

Crystalline SiO2: none detected

ADDITIONAL INFORMATION and SUPPORT DOCUMENTS:

» Download: Technical Data Sheet (PDF)

» Pumice Safety Data Sheet (PDF)