PUMICE CONCRETE is composed of Portland cement, pumice stones, pumice sand, pumice powder (pozzolan), and water. Compared to standard concrete, pumice concrete offers roughly a one-third reduction in weight and four times the r-value. Proportioning, mixing and placing are done in a similar manner to that of standard concrete. (Download our Mixing and Placing Pumice Concrete Tip Sheet) Pumice concrete is placed and finished with typical concrete equipment and tools and is used, with one exception, for the same applications as sand and gravel concrete. That exception: due to the grippy nature of pumice aggregate and sand, pumice concrete takes more effort and patience to work to a standard surface finish, and for that reason is rarely used for extensive flatwork. But for limited flatwork projects and all applications where pumice concrete is vibrated into forms, (like precast applications) it presents no placement challenges beyond standard concrete and actually presents several advantages. (Download Pumice Concrete Mix Designs)

Pumice concrete has superior resistance to harsh weather conditions like freezing and thawing and an R-value some four-times that of ordinary sand and gravel concrete—making pumice concrete ideal for colder climates and locations that experience dramatic fluctuations in the weather and temperature. Pumice concrete is also sound absorptive, more elastic than conventional concrete, and will not spall under direct contact with flame.

Pumice is a porous, naturally-occuring volcanic glass, riven with air-filled vesicles formed by the expansion of trapped gasses when the molten lava is expelled into the air and flash-cools. It is this amorphous, cell-filled nature of each stone that give pumice it’s lightweight and insulative characteristics. Pumice is also an inert material and therefore will not react with the reinforcing steel or any other concrete component.

For additional information on pumice-based lightweight insulative concrete, visit our Pumice and Concrete website.

The Alkali Silica Reaction (ASR)

It’s important to know and understand that lightweight aggregates are reactive (high silica content) and need a pozzolan to mitigate ASR. It’s one of concrete science’s ironic truths: if lightweight aggregates (or any high-silica aggregate types) are used with Portland cement without the mitigating effects of a reactive pozzolan, the concrete inevitably develops a nasty ASR problem—a reaction between the silica content in the aggregate and the alkali in the hydrated cement paste. The alkali-silica reaction forms expansive gels that generate a sort of slow-motion explosion, map-cracking and eventually destroying concrete structures from the inside out. Adding a high-quality pozzolan—and here’s where the irony lies—made from the same pumice as the aggregate, but milled to a fine powder, ignites an immediate (secondary) reaction within the hydrated lime paste, consuming the deleterious calcium hydroxide (CH) generated by the primary cementitious reaction. Without that CH, there’s no fuel to trigger ASR.

Learn more about mitigating ASR by downloading this whitepaper: Flatline Alkali-Silica Reaction with Pumice-Blended Cement.

ADDITIONAL INFORMATION and SUPPORT DOCUMENTS:

» Technical Data Info: the physical and chemical properties of our pumice

» Pumice Safety Data Sheet (PDF)

» Base Mix Designs for Pumice Concrete (PDF)

» Properties of Hess Pumice Aggregate (PDF)

» Tip Sheet for Mixing and Placing Pumice Concrete (PDF)

» Whitepaper: Flatline Alkali-Silica Reaction with Pumice-Blended Cement

» Website: PumiceConcrete.com

» Website: InsulativeConcrete.com

Order Pumice Aggregate

PLEASE READ THE SHIPPING NOTES BELOW BEFORE PLACING AN ORDER.

SHIPPING NOTES

Information about turn-around times, auto-calculated shipping, obtaining shipping rates for large orders, more.

| LIGHTWEIGHT CONCRETE AGGREGATE (CONSTRUCTION STANDARD) |

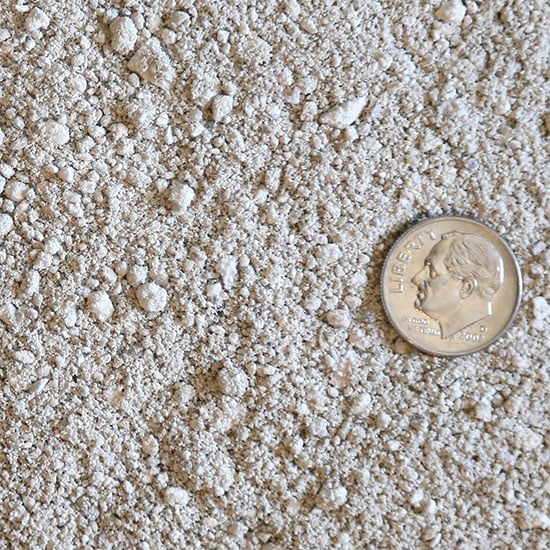

| Lightweight pumice aggregate for formed construction concrete. NOTE: the addition of pumice pozzolan (a microfine powder) will provide additional density and strength to cast concrete as well as mitigate ASR. » Size/Grade: Lightweight Standard Aggregate (3/4 to 5/16-inch stones with some adhered fines/sand) |

| BUY LIGHTWEIGHT PUMICE AGGREGATE (CONSTRUCTION STANDARD) |

| LIGHTWEIGHT CONCRETE AGGREGATE (CRAFT) |

| Lightweight pumice aggregate for craft-type precast concrete projects—including statuary, containers, pavers—where a smaller aggregate size is desirable. NOTE: the addition of pumice pozzolan (a microfine powder) will provide additional density and strength to cast concrete as well as mitigate ASR. » Size/Grade: Lightweight Craft Aggregate (3/8 to 1/8-inch stones with some adhered fines/sand) |

| BUY LIGHTWEIGHT PUMICE AGGREGATE (CRAFT) |

| LIGHTWEIGHT PUMICE SAND + |

| Lightweight pumice sand + (includes) tiny 1/8-inch stones. Use in lighweight mortars and as an additive to the craft aggregate when more sand content is desired. Also used for lightweight insulative plasters. » Size/Grade: Pumice Sand + (pumice sand also containing up to 1/8-inch stones) |

| BUY LIGHTWEIGHT PUMICE SAND + |