IT’S ALL ABOUT THE FINISH. The final micro-sanding and rubbing steps in finishing wood (or metal) is what takes the quality of a piece from average to amazing.

Liquid finishes, whether applied with a spray gun (micro-bumps) or brush (drag ridges), never cure perfectly flat. And then there’s the dust motes drifting down and rooting into the curing surface. Rubbing up the finish with a superfine abrasive knocks down those flaws and greatly improves surface appearance, especially when lit.

FULL CURE: Allow for a complete cure—the complete absence of solvent smell—before rubbing the finish coat(s). Some finish formulations take longer to cure than others—some varnishes, for example, should be left alone for several weeks. Finish experts advise at least 3 coats of a film-building type finish, but coat-count depends on several factors, including the porosity of the wood, degree of finish thinning, and thickness of application.

LUBRICANTS: The use of lubricants with Sedoso™ finish grits controls the cutting rate—dry grit is the most aggressive. Use the right lubricant for the finish chemistry type. For example, do not use mineral spirits on water-based finishes.

THE STROKE: Use long straight strokes that track with the grain of the wood. Maintain an even pressure. Seek expert advice on rubbing techniques to avoid rubbing through the finish on the corners. And this: let the grit do the work, not application pressure, which cannot be held consistent.

APPLICATORS: Use felt pads, cotton cloth, and cotton string or rope (various diameters to work valleys on lathe-turned pieces). When finishing flat surfaces, wrap the applicator around a stiffener to even out pressure consistency.

REMOVE THE DUST: Before applying a finish coat, remove the pumice and cut-material dust. If blowing off, allow a generous amount of time for the dust to settle. After blow-off, brush-off, or vacuum-off, wipe surface with a clean, lint-free cloth dampened with water or mineral spirits. Tack clothes work too. Match nature of wetting compound to finish type. Repeat as necessary, rotating to a clean cloth surface often to avoid redepositing dust.

A PROGRESSIVE PROCESS: Various sanding and finishing grit grades are available because the most effective way to get to the desired level of visual smoothness and gleam is to work through progressive grits, with the coarser grits doing the leveling and blemish removal, and the finer grits erasing the scaring left behind by the coarser stuff.

SAY IT: Pronounced say-doe-so. Sedoso means “silky” in spanish.

| SEDOSO™ GRADE SIZE to EQUIVALENTS | ||

| SEDOSO™ GRADE | MICRON | OTHER |

| SEDOSO X2 | 24-28µm | (FF) |

| SEDOSO X3 | 22-25µm | (FFF) |

| SEDOSO X4 | 16-18µm | (FFFF) |

| SEDOSO XRS | 12-14µm | (ROTTENSTONE) | NOTE: Mean (average) micron size range is determined via laser diffraction. Pumice dust is non-spherical in shape, so sizes are approximate, with the degradation in accuracy becoming more pronounced in the larger particle sizes. |

ADDITIONAL INFORMATION and SUPPORT DOCUMENTS:

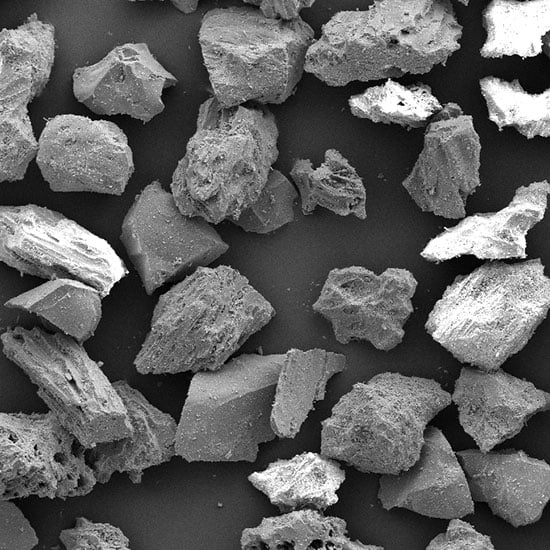

» Technical Data: the physical and chemical properties of our natural pumice.

» Pumice Safety Data Sheet (PDF)

Order Sedoso

PLEASE READ THE SHIPPING NOTES BELOW BEFORE PLACING AN ORDER.

SHIPPING NOTES

Information about turn-around times, auto-calculated shipping, obtaining shipping rates for large orders, more.

| SEDOSO™ X2 (MEDIUM FINE) |

| Medium Fine Pumice Sanding Grit imparts a silky finish to detailed wood or metal surfaces. Loose pumice powder is applied and worked using a rubbing cloth or felt pad to smooth detail areas. Can be used dry or dampened with water, mineral spirits, or denatured alcohol. Match lubricant type to cured finish type. |

| BUY SEDOSO X2 PUMICE SANDING GRIT |

| SEDOSO™ X3 (FINE) |

| Fine Pumice Finishing Grit imparts a silky finish to detailed wood surfaces. Loose pumice powder is applied and worked using a rubbing cloth dampened with water, mineral spirits, or denatured alcohol. Match lubricant type to cured finish type. |

| BUY SEDOSO X3 PUMICE FINISHING GRIT |

| SEDOSO™ X4 (EXTRA FINE) |

| Extra Fine Pumice Finishing Grit imparts a silky finish to wood, metal, and stone surfaces. Loose pumice powder is applied and worked using a rubbing cloth dampened with water, mineral spirits, or denatured alcohol. Match lubricant type to cured finish type. If using to rub-up a finish, use only after finish is fully cured (hardened). |

| BUY SEDOSO X4 PUMICE FINISHING GRIT |

| SEDOSO™ XRS (ULTRAFINE) |

| Ultrafine Pumice Polishing Grit for rubbing up the final finish coat to polish level desired. Loose pumice powder is applied and worked using a rubbing cloth, felt pad, or rotary buffer and a rubbing oil lubricant. Sedoso XRS has the foamed-stone friability and particle-size equivalence of a typical rottenstone powdered polish, thus the XRS designation. Use only on fully cured (hardened) finishes. |

| BUY SEDOSO XRS PUMICE FINISHING GRIT |