WHEN IT COMES TO CLEANING rusty, painted, or grime-smeared surfaces, sandblasting gets it done quickly and completely—and without having to open a bucket of elbow grease. And with the right blast media, you can go beyond simple cleaning and produce a smooth, satiny polish.

There is a welcome variety of sandblasting gear on the market, from hoppered guns you jack into your own compressor to bench-top cabinets for small parts and delicate work. But quality results are closely tied to matching the right blast media to the situation.

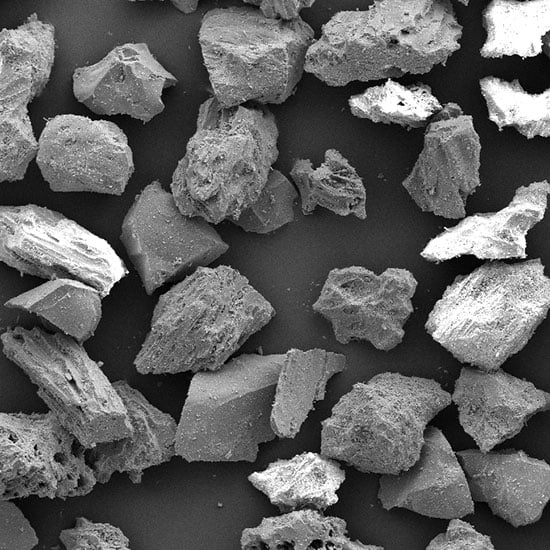

Sand itself is falling out of favor (high moisture and hazardous crystalline silica content), but a nice selection of blast media are available to meet every need. Along with media type, grit size is another factor to work into your choice. The key to choosing the right blast media is to focus first on the surface: how much can it handle without damage? If in doubt, start soft and fine.

The foamed-glass nature of pumice makes it an effectively mild, lightweight abrasive and a good fit for those less aggressive or delicate situations where protecting the surface is the primary consideration. Why? Pumice, even crushed to a superfine grade, holds its angular shape and myriad edges to cut quickly and aggressively, removing rust, scale, and a variety of coatings from wood, metal and plastic surfaces. Combine that excellent bite with pumice’s low, sponge-like density and you’ve got an easy-on-the-surface sand blast media with a highly effective reputation.

PUMICE BLAST MEDIA (GENERAL):

Physical Profile: Foamed Glass Stone

Surface Profile: Low Etch

Working Speed: Medium-Slow

Recyclability: Low

Surface Removal: None

Hardness (Mohs): 6

Bulk Density: 46-58 lbs/cf3

ADDITIONAL INFORMATION and SUPPORT DOCUMENTS:

» Technical Data: the physical and chemical properties of our natural pumice.

» Pumice Safety Data Sheet (PDF)

Order Sand Blasting Grit

PLEASE READ THE SHIPPING NOTES BELOW BEFORE PLACING AN ORDER.

SHIPPING NOTES

Information about turn-around times, auto-calculated shipping, obtaining shipping rates for large orders, more.

| STANDARD BLASTING GRIT (SBH) |

| Our Sand Blast Standard (SBH) grade grit contains a small percentage of obsidian and perlite ore sand (igneous minerals) blended with the softer pumice sand, providing bite without being too agressive overall. |

| BUY SAND BLAST STANDARD (SBH) GRIT |

| SOFT BLASTING GRIT (SBS) |

| Our Sand Blast Soft (SBS) grade contains pure pumice sand for use on soft or delicate surfaces. |

| BUY SAND BLAST SOFT (SBS) GRIT |

| FINE BLASTING GRIT (SBF) |

| The Sand Blast Fine (SBF) grade is for delicate and/or small, intricate surfaces. Typically used in bench-top sand blast cabinets. Also applicable for fine-tipped sand blast guns on larger detailed surfaces, such as carved wood, plaster moldings, and plastics. |

| BUY SAND BLAST FINE (SBF) GRIT |